ITW Automotive has a long history of innovation including heating solutions for seats, mirrors and ADAS sensors in the automotive industry. As the industry faces challenges in reaching higher levels of automated driving, ITW is helping partners improve camera uptime by reducing water-based and stray light induced blockages.

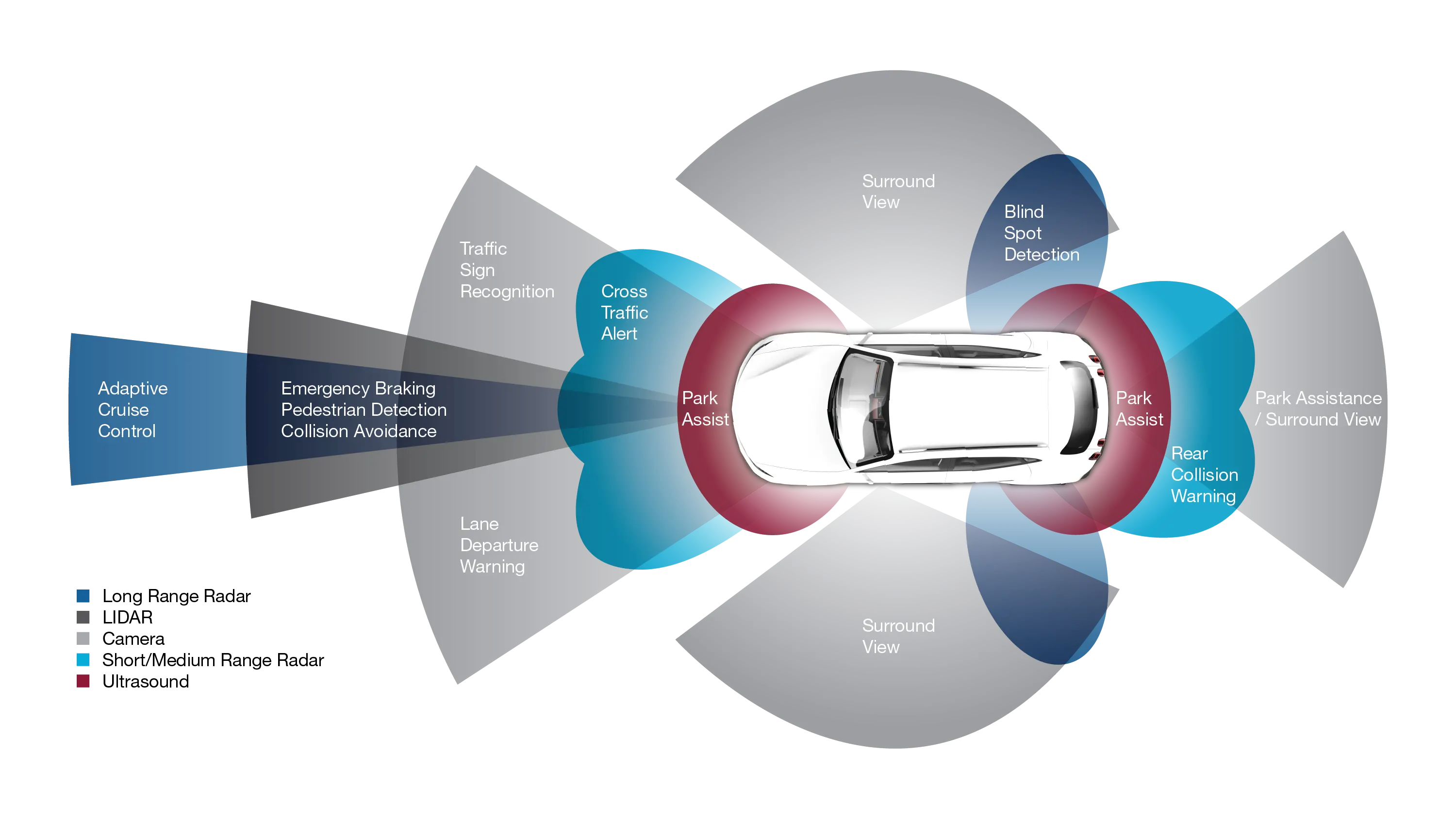

The automotive industry has come a long way on the path to hands free driving, as seen in ADAS levels 3, 4 and 5 using camera sensors as the predominate method of perception. Cameras are used in many ADAS systems such as Lane Keeping Assist, Automatic Emergency Braking (AEB), and object detection & classification, allowing systems to detect other vehicles, pedestrians, and signs. However, camera system performance is dependent on its ability to “see” clearly. Blockages from environmental factors, particularly weather conditions such as rain, sleet, snow, and ice, degrade and can even blind the camera, resulting in loss of driver assistance and safety features. Wiper systems may address rain in some cases but are not effective when temperatures drop in wet conditions. Sleet, snow, and ice can develop on a windshield in the field of view of the camera and will prevent light from entering the camera. Another challenge to camera systems which prevent them from “seeing” clearly is stray light. Commonly known as glare, it is caused by external light sources reflecting off adjacent surfaces or shining directly into the camera sensor, reducing the contrast in the captured image. The low contrast area masks the real scene from the sensor which contains critical information such as vehicles, pedestrians, and road markings. This occurrence can limit the camera system’s capability or fully prevent the system from operating, which ultimately disables critical ADAS systems such as AEB and Lane Keeping Assist.

ITW’s solution to these challenges is an integrated camera bracket system that combines our precision molded camera bracket with our flexible heating technology and industry leading glare mitigation solutions. We tailor the system to meet customers’ power requirements, packaging, shape constraints, and clearing time requirements to give optimal performance for each application.

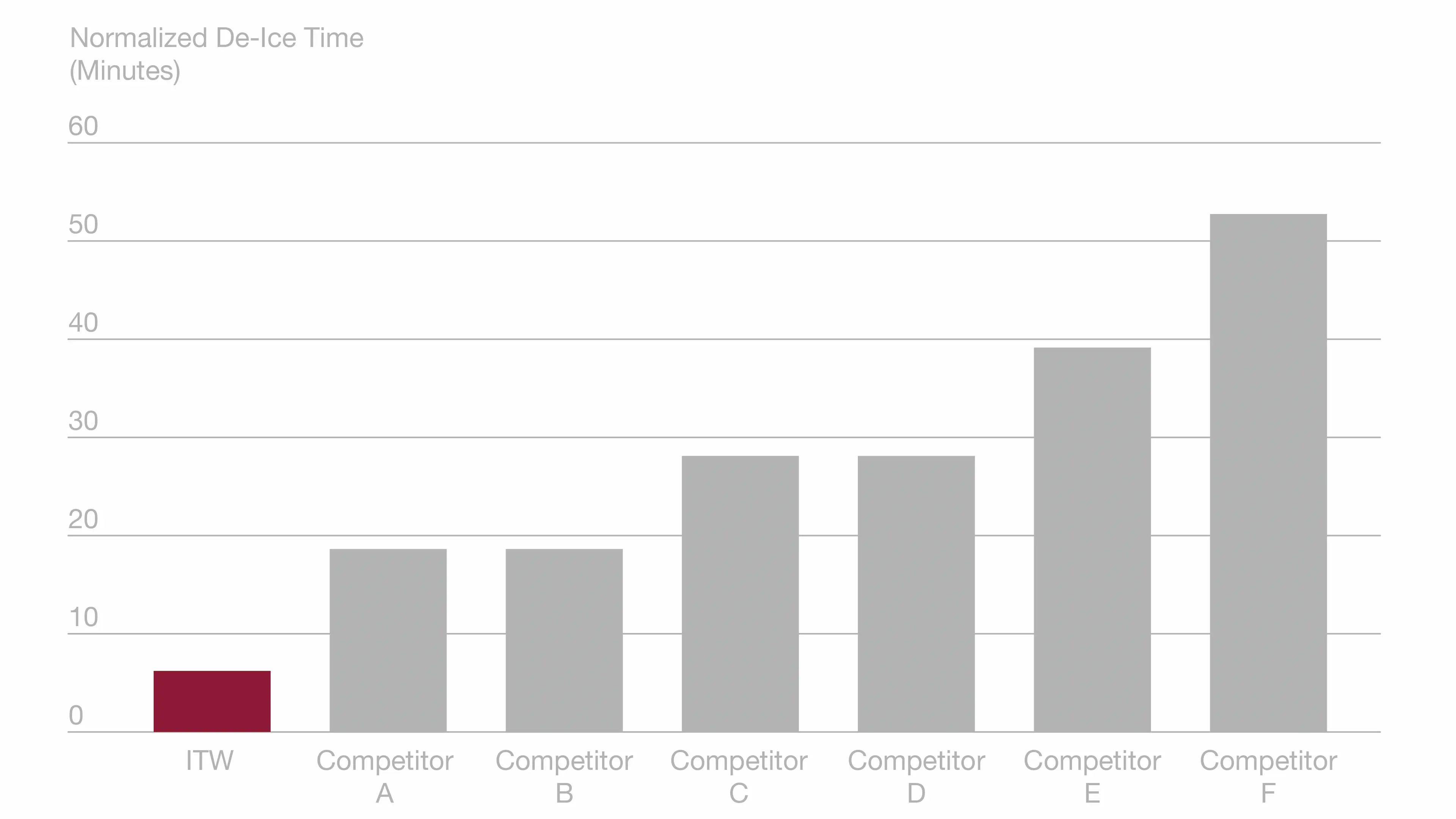

The superior efficiency obtained from our printed conductive ink technology is demonstrated in a benchmark study with other late model ADAS camera bracket and heating systems.

Plastic injection molding has been an ITW core capability for decades. We have the expertise to produce high quality molded parts that hold to the tightest of specifications for dimensionality and warpage. Additionally, we offer customers integration support to design the bracket, heating solution and glare solution as a single system. The system approach to design ensures customer project outcomes are achieved with a single partner.

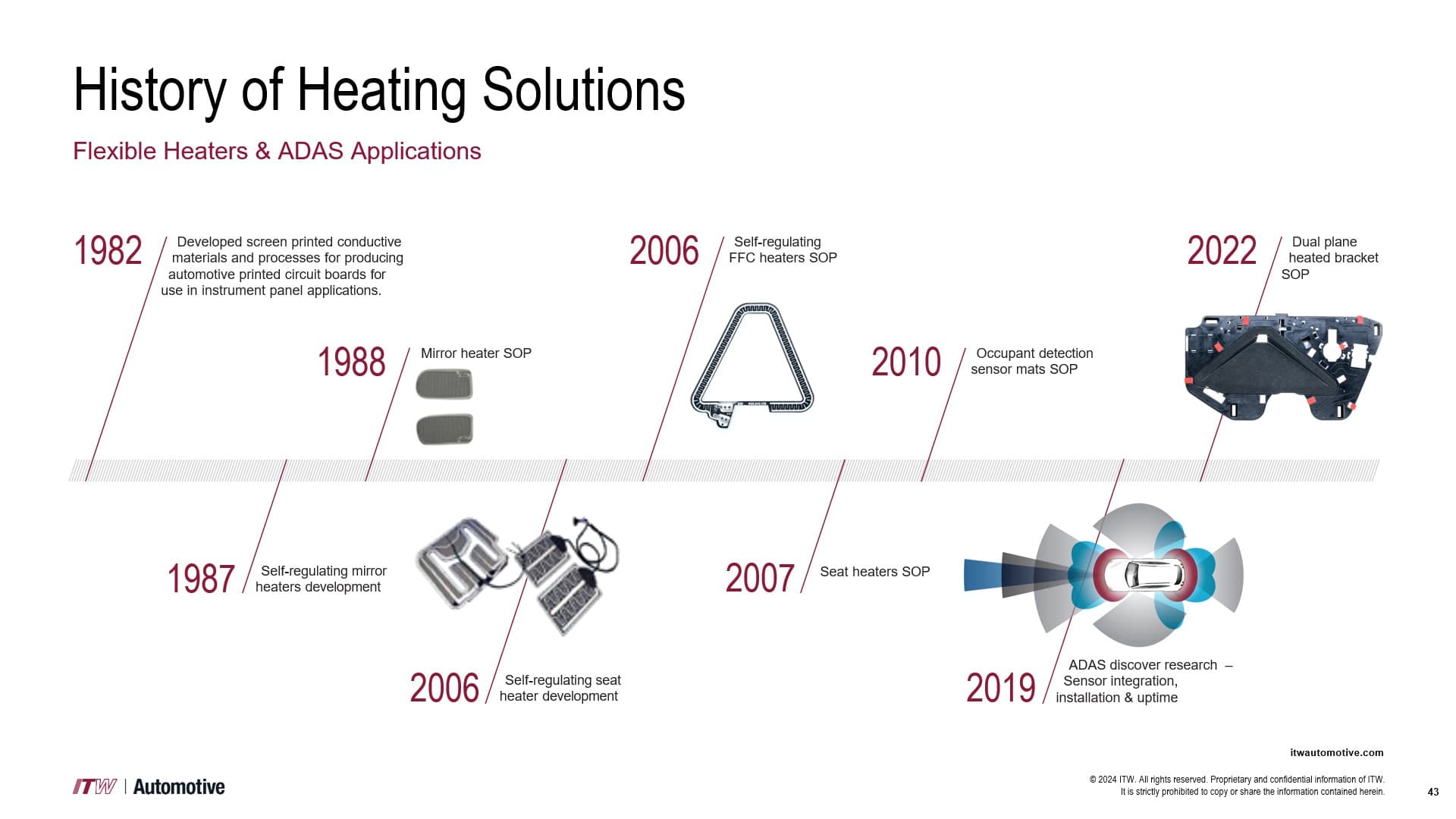

ITW Automotive has a long history of innovating and manufacturing heating solutions for over 35 years, beginning in 1982 when we developed a proprietary printable conductive ink and process for use in automotive instrument panels. The discovery that one ink formulation made for a predictable and effective heating element opened the door to heating applications all over the vehicle. In 1988, our self-regulating mirror heater was developed with over 500 million parts built into vehicles. Self-regulating heaters for forward-facing cameras were developed in 2006 with over 7 million units shipped. The following year self-regulating seat heaters were launched onto the market with over 9 million parts shipped. Today, ITW Automotive has a dedicated division that focuses on Advanced Driver Assistance Systems (ADAS) and increasing the uptime and performance of the sensors used in these systems. Our core capabilities include injection molding and manufacturing flexible heating elements.

These capabilities, combined with our efficient heating technology, and industry-leading glare control materials present a superior value to our customers in system performance, integration efficiencies, and supply chain simplification.