The automation of cable set production is accelerating rapidly, transforming the landscape of automotive manufacturing. ITW Automotive’s Plastic Fasteners Division is leading this evolution with an innovative production concept for bonded fasteners. This cutting-edge approach is defined by a high degree of standardization, ongoing process chain validation, and numerous of cost and process efficiencies.

The vehicle electrical system is one of the last disciplines in automotive manufacturing which is not manufactured automatically. The size, complexity, variety, and the flexible structure of vehicle electrical systems were previously arguments against robot-assisted manufacturing.

However, the economic and geopolitical upheavals that have taken place over the last few years have motivated automotive manufacturers and vehicle electrical system suppliers to bring cable set production closer to vehicle production again in order to boost supply chain resilience. Automated systems are essential to meet these new demands for cost and quality. ITW is able to provide a decisive impetus for this type of automated production with a production concept for bonded fasteners.

Reliable processes

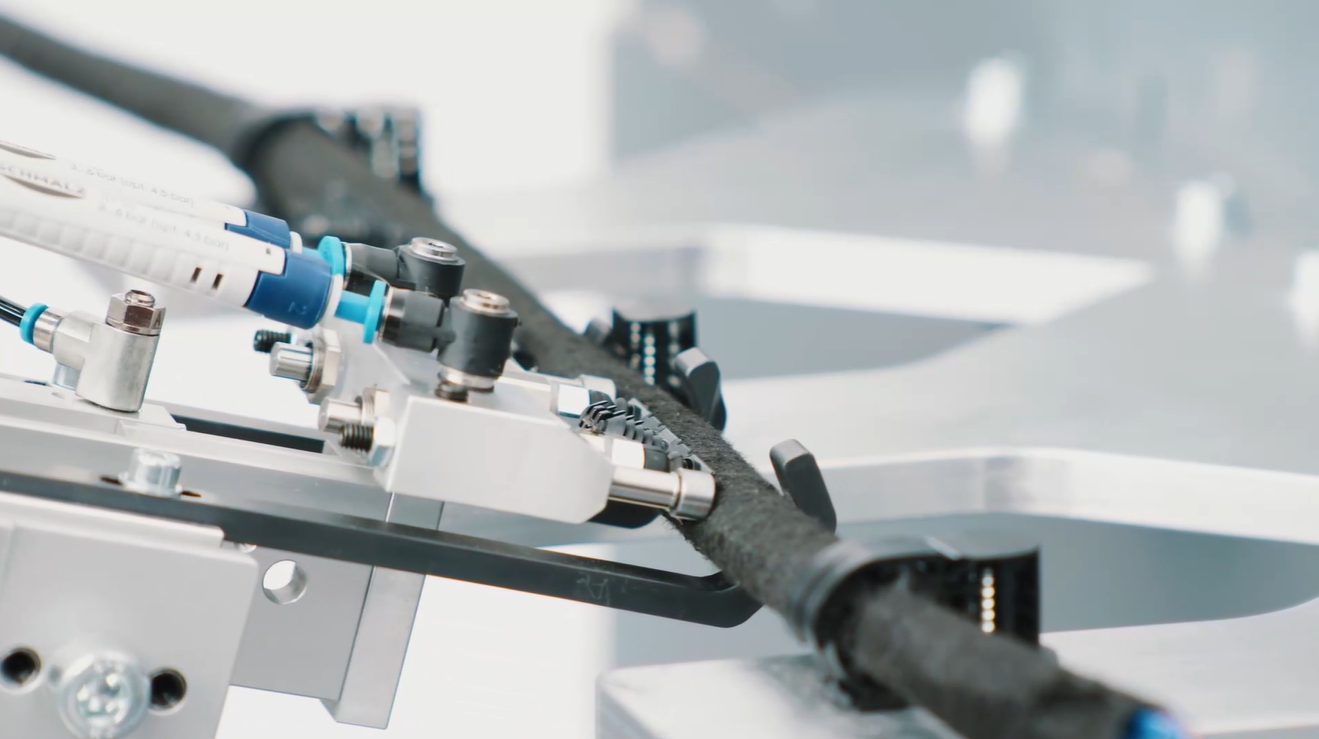

ITW Automotive has developed a continuous process concept for bonded fasteners. This continuous process solution is validated for interactions between adhesive bonds and the various types of winding tape available on the market. Important considerations include process reliability, cost efficiency, and locator geometry to ensure machine-compatible processing. Simplified automated prototype production has demonstrated proof of concept. Key steps in the fully automated process include:

Standardization provides flexibility

Several beneficial design details were integrated into the concept. The locator features two standardized contact surfaces for the vacuum gripper, regardless of the geometry of the connecting element. This allows various locators to be handled on one cable set with a single standard setting head. They can be combined with manual winding technology initially and later with an automated winding process or as a standalone adhesive bond. The adhesive used ensures holding forces of up to 600 Newtons, significantly above the required 100 to 150 Newtons.

Modular expansion

Flexibility and modularity play a key role for cable set producers. With ITW Automotive adhesive technology, automated production lines can easily be expanded with separators, robots, and setting heads to shorten cycle times or to place additional locator variants on the same wiring harness.

Comparative Advantages

Compared to previous fastener solutions, such as cable ties and adhesive tape, bonding is simpler, faster, more reliable, and involves comparatively low investment costs. The small locators and streamlined setting head can be easily inserted into narrow gaps between the mounting panel and the wiring harness, ensuring good all-round accessibility. Competing concepts require significantly more space, and bonded locators can be placed closer to interference contours than competing processes allow.

Future Integration and Compliance

The ITW Automotive adhesive technology enables greater design freedom than competing concepts and is significantly more cost-effective. The concept complies with the fundamental recommendations of DIN 72036, which will soon be published. ITW Automotive has presented the concept with bonded fasteners to premium OEMs in southern Germany and is collaborating with one of them on concept approval. If these tests are successful, cable set manufacturers could integrate the adhesive technology into their initial automated production concepts for this premium OEM.

Collaborative Support

ITW Automotive stands ready to support partners with fasteners suitable for automation, setting head technology, and expertise in the entire production concept, fostering advancements in automotive manufacturing.