The Sustainable Cable Grommet for Quick and Reliable Assembly

Recycling and resource efficiency are key levers on the road to a more sustainable automotive industry. Increasingly, even small plastic components are gaining importance — because their contribution to a vehicle’s environmental footprint is greater than it may seem at first glance.

The European Union’s proposed end-of-life vehicle regulation sets ambitious targets: by 2030, at least 25% of the plastics used in new vehicles must come from recycled material. In addition, 95% of a vehicle’s weight must already be reusable or recoverable, including both material and energy recovery. These requirements fundamentally change how components are viewed: recyclability and resource efficiency are now just as important in design as functionality and cost.

A modern car contains several hundred plastic components — from cockpit elements to small cable fasteners. Even seemingly minor parts such as cable grommets quickly add up to millions of units in production. If made from materials that are difficult to recycle, they can have a significant negative effect on the overall balance.

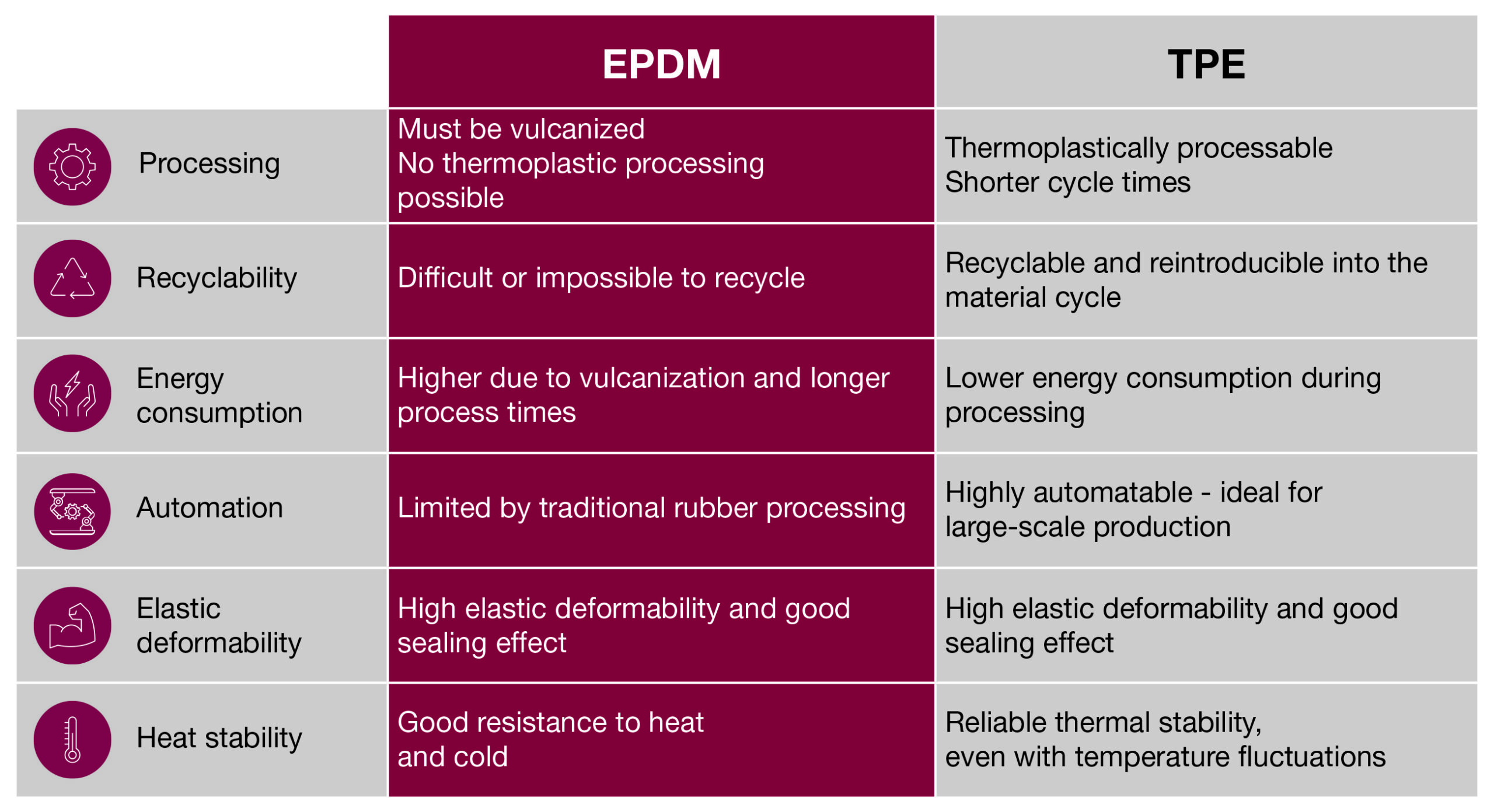

Many of these parts have traditionally been produced from elastomers such as EPDM, which cannot be thermally reprocessed — an obstacle to true circularity. Yet these very small parts hold major potential: by substituting materials and applying smarter design, weight and environmental impact can be reduced. Every material replaced helps reduce CO₂ emissions across the entire vehicle lifecycle.

Thermoplastic elastomers (TPE) offer a forward-looking alternative. Unlike conventional rubber materials, they can be thermoplastically processed, remelted, and reintroduced into the material cycle. For large-scale production, this means shorter cycle times, lower energy consumption, improved automation — and the ability to directly incorporate recycled material.

In practice, TPEs deliver high flexibility, strong sealing, and reliable thermal stability. This makes them ideal for components that are frequently assembled, moved, or exposed to temperature variations—such as cable pass-throughs inside the vehicle or in door modules.

Rethinking Assembly

ERGOFASTEX™ Grommets were designed to significantly simplify assembly processes in automotive production. Thanks to their ergonomic design, they can be installed in just seconds without the need for tools. The insertion force is minimal, while tactile, audible, and visual feedback immediately confirm proper installation. In practice, this translates into assembly time reductions of up to 90%—a benefit that quickly adds up in high-volume production.

In addition, the grommets deliver reliable sealing performance (IPX6K), temperature resistance up to 100 °C, and come in a wide range of variants for diverse installation scenarios.

Sustainability Ready for Series Production

The Greenline variant goes a step further. Up to 50% of the material used is sourced from recycled plastics, conserving resources while significantly reducing part weight. This lowers energy demand in both manufacturing and vehicle operation and improves recyclability at the end of the lifecycle. In this way, ERGOFASTEX™ Greenline combines assembly efficiency with a measurable contribution to sustainability.

Key benefits at a glance:

Whether in door modules, battery housings, or body pass-throughs — the ERGOFASTEX™ Greenline demonstrates that even small components can make a measurable contribution to meeting regulatory requirements and advancing the industry’s transformation toward greater sustainability.