Innovation begins with trust and collaboration. Let’s work together.

We collaborate with you every step of the way to design and engineer solutions that meet your precise needs. Our world-class manufacturing enables us to deliver products with unmatched speed, scale, and quality – anywhere in the world.

Innovation begins with trust and collaboration. Let’s work together.

We’ll work with you to understand your challenges, suggest brilliant and innovative solutions, and ensure those solutions turn into products that are fully tested and validated according to your specifications and industry best practice before production. When we produce, we do it with quality, speed and scale. And we fully support what we make – the world over.

A century of industry leadership

At ITW Automotive, we count all of the major automotive manufacturers and tier suppliers as customers. Our research and development teams work in modern innovation centers – like our newest, the New Mobility Innovation Center in Shanghai, China – and with you in your engineering centers and assembly plants. We’re well-positioned to understand regulations and their impact on trends and emerging technology and materials. We have a comprehensive view of the industry, and the expertise to apply our knowledge and experience to solving your challenges.

Customer-Back Innovation

Customer-Back Innovation (CBI) is a proprietary ITW business process that prioritizes our customers at every step. It begins with a thorough understanding of your challenges, pain points, and needs. Through this process, we achieve a thorough understanding of the issue and its business implications, explore multiple options, and ultimately devise and execute the solution that maximizes value for both you and your customers. CBI is in our DNA, and it has enabled ITW Automotive to help solve problems and delight customers across the markets ITW serves.

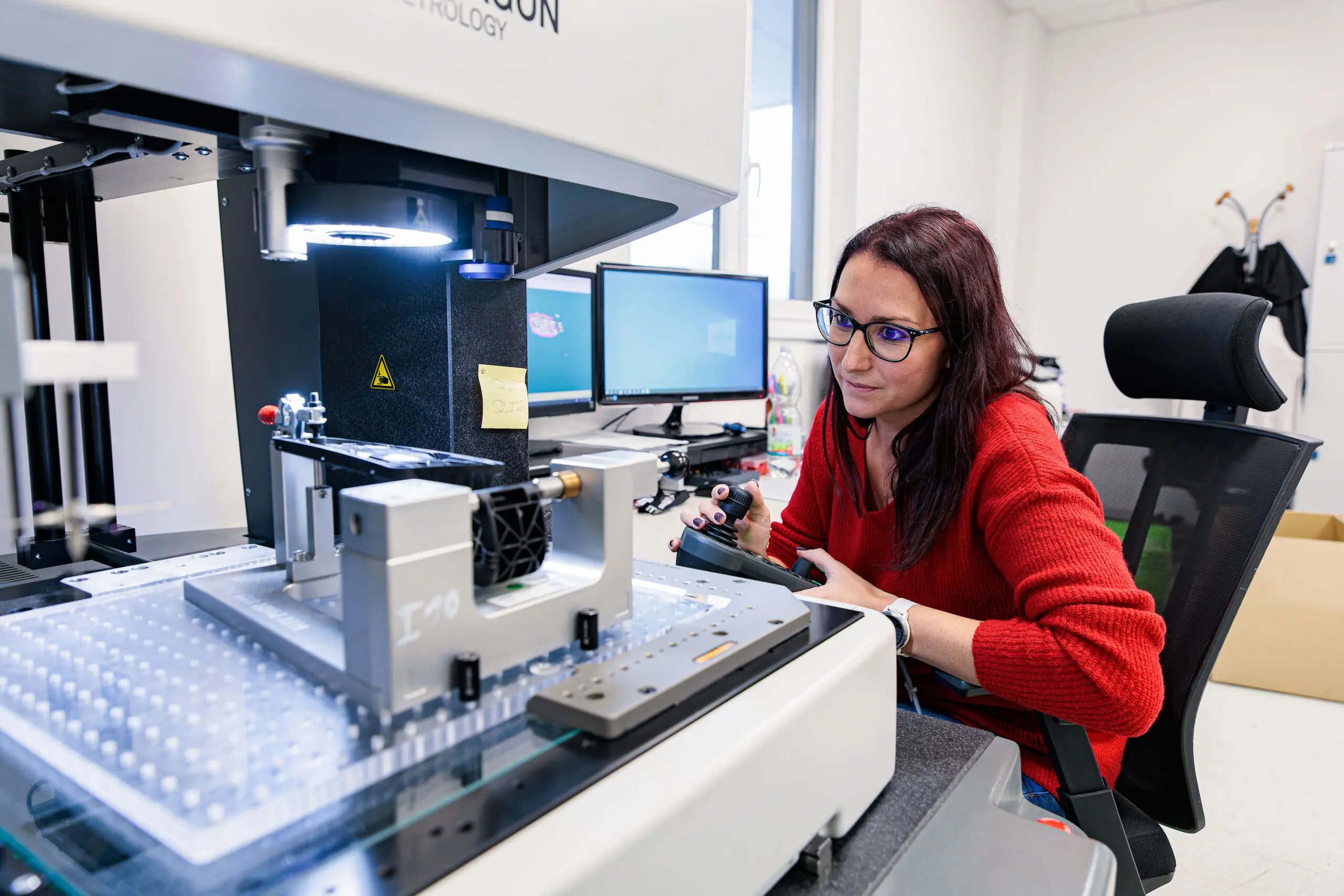

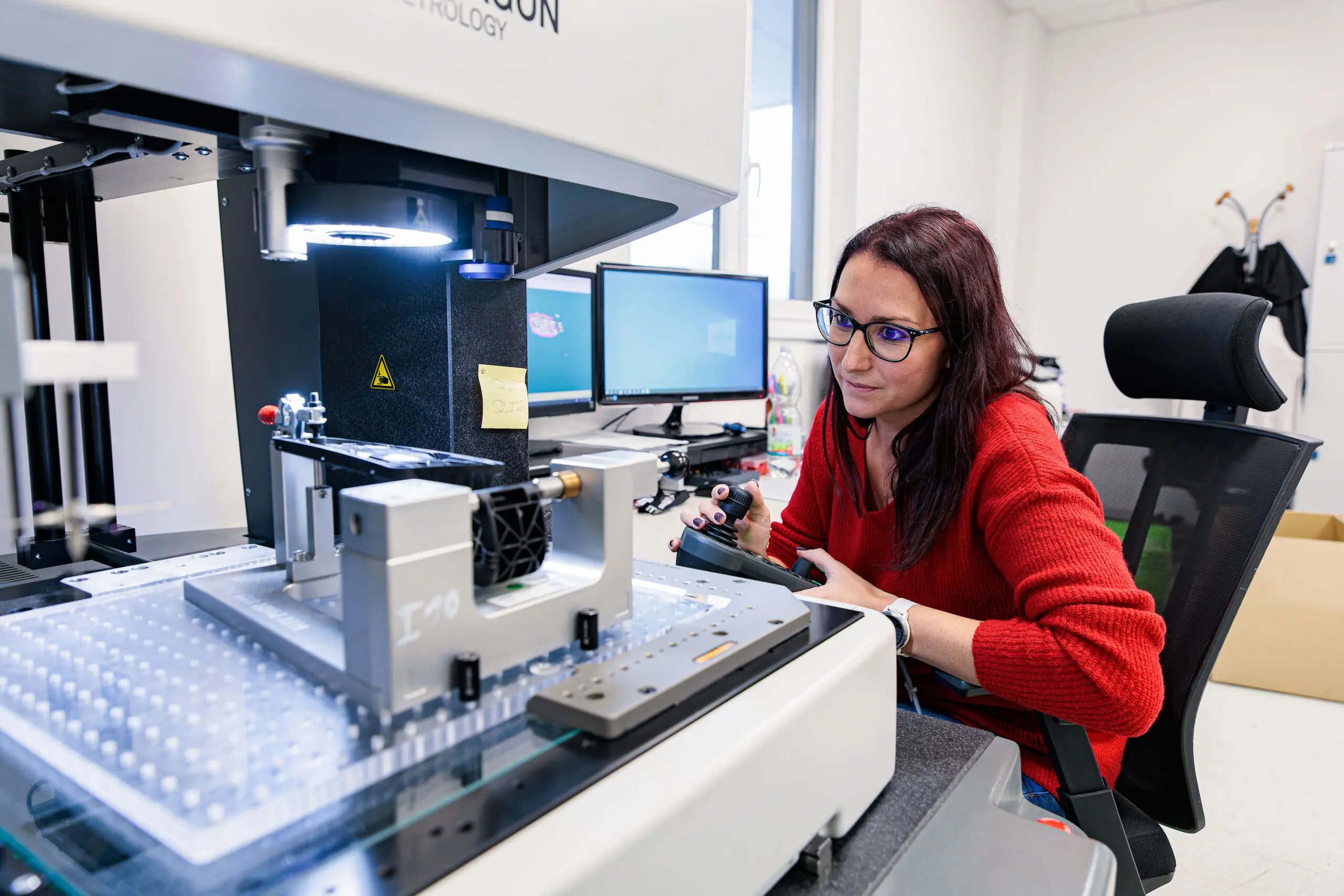

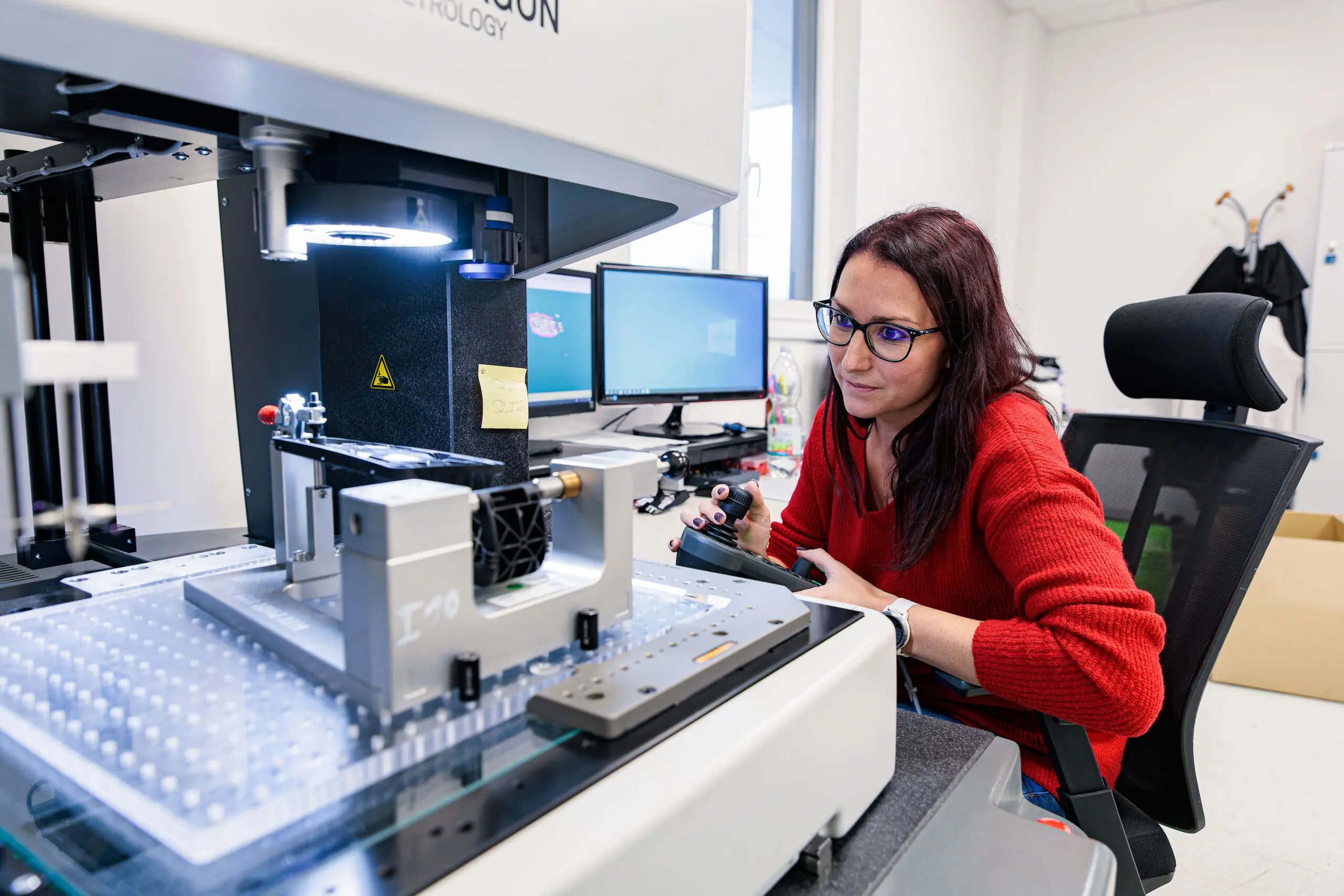

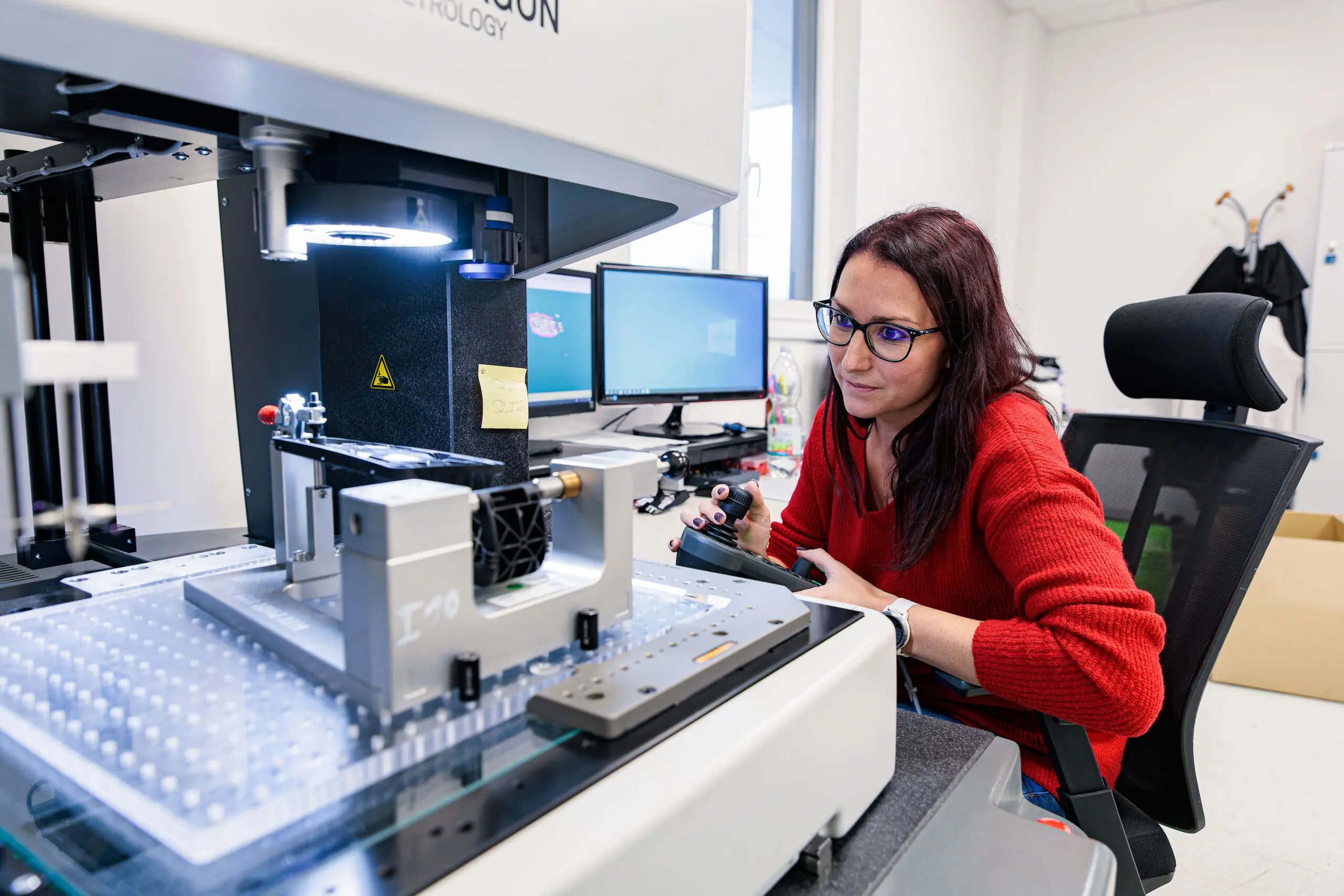

Intelligent design & development

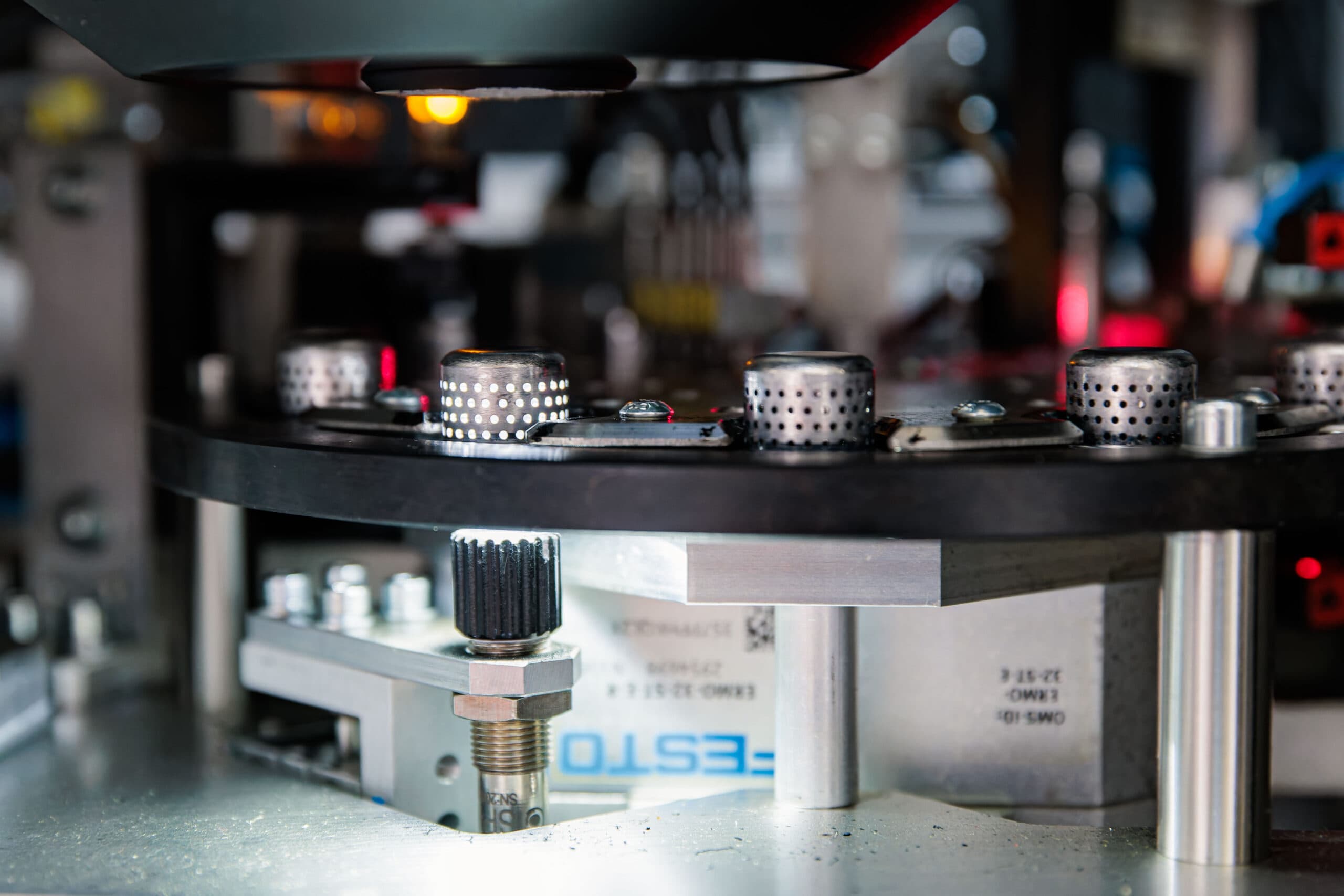

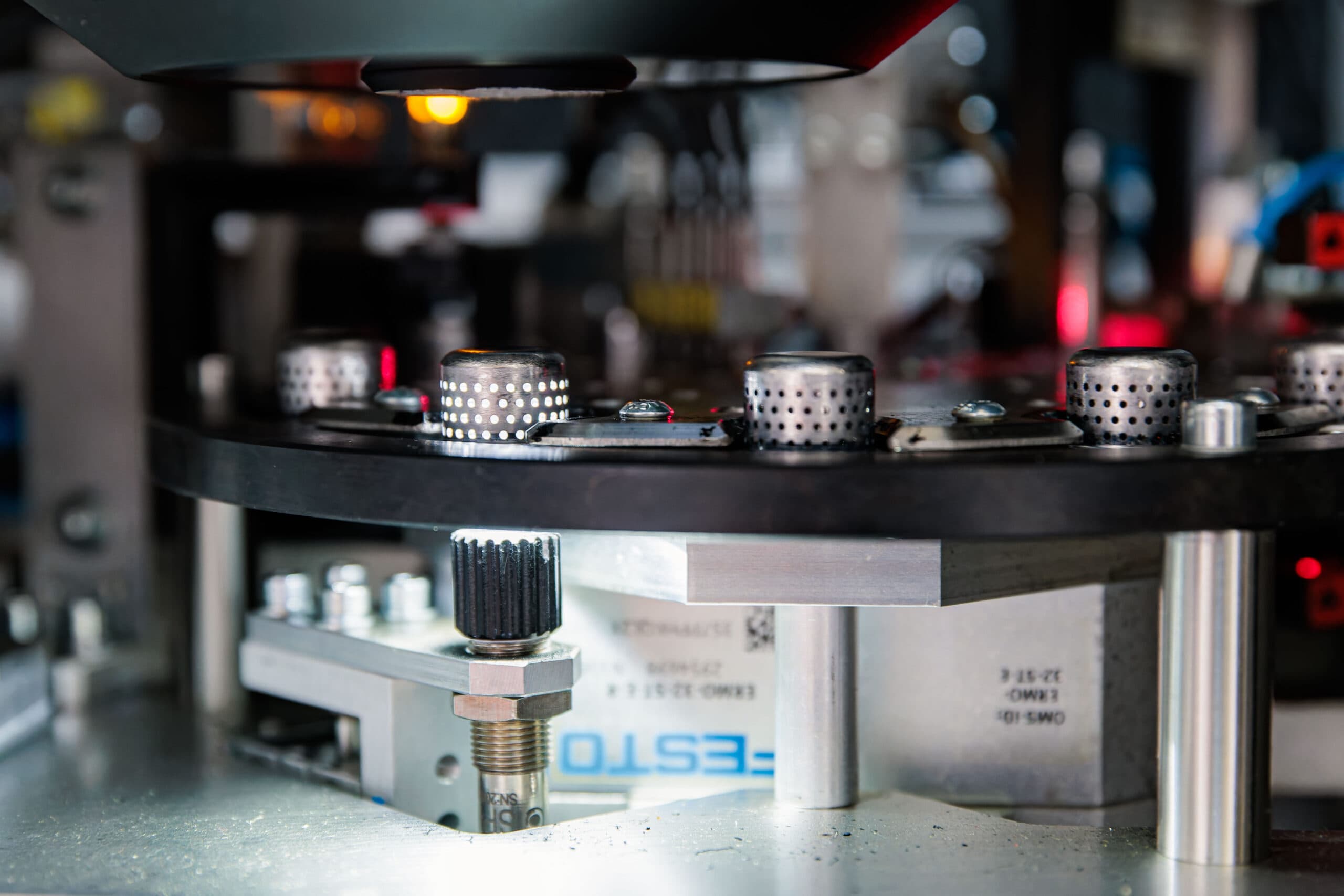

When it’s time to bring ideas to life, we do it efficiently. Our teams utilize a comprehensive toolkit to simulate product concepts and analyze data. Prototypes are created with state-of-the-art methods, including additive manufacturing. We are well-versed in and capable of applying the full range of design and construction methods and tests typically required to validate the performance of our automotive products, including Finite Element Analysis (FEA), Noise Vibration & Harshness (NVH) simulation, material fatigue, fluid dynamics, electromagnetic (EM) interference, pressure, and more.

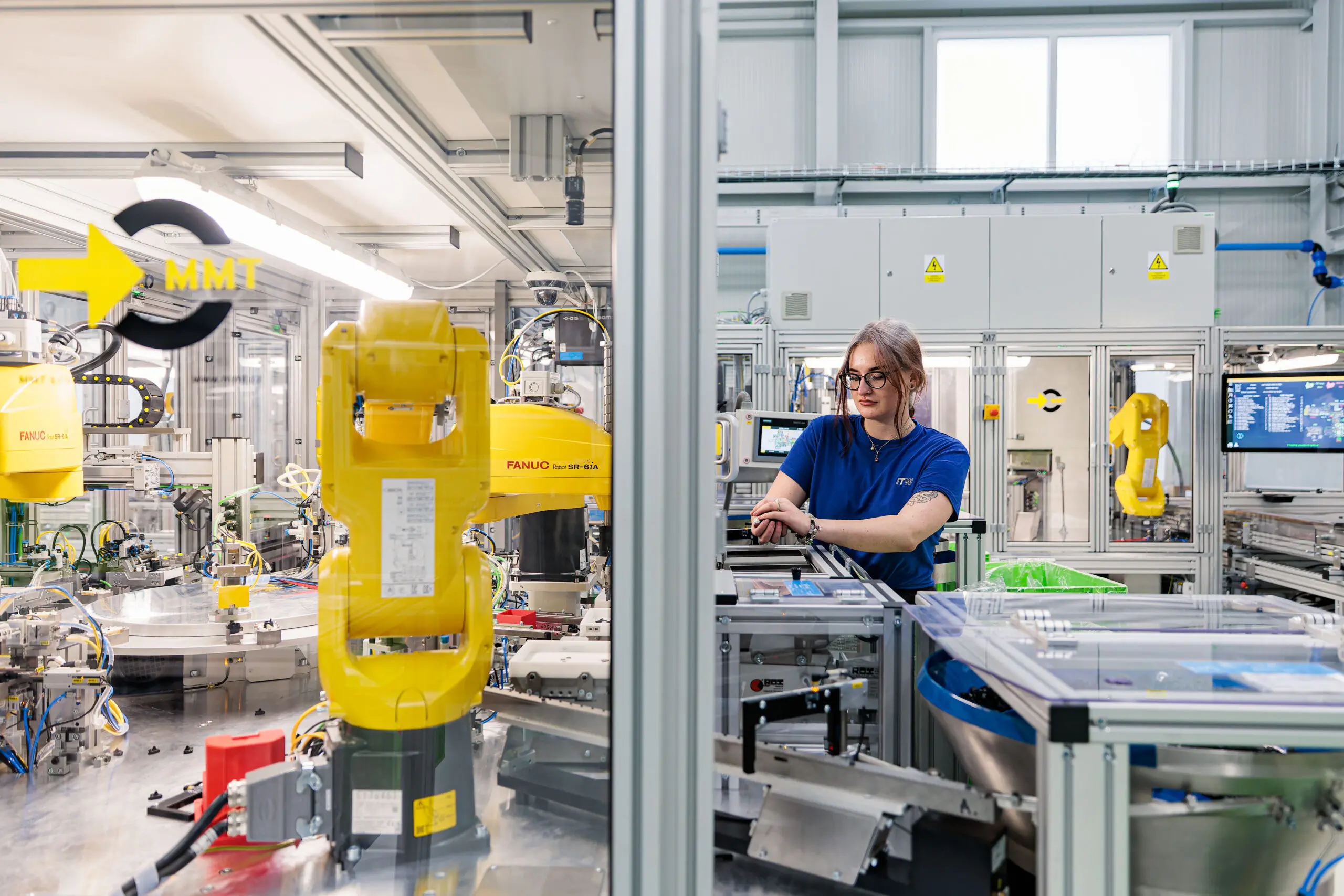

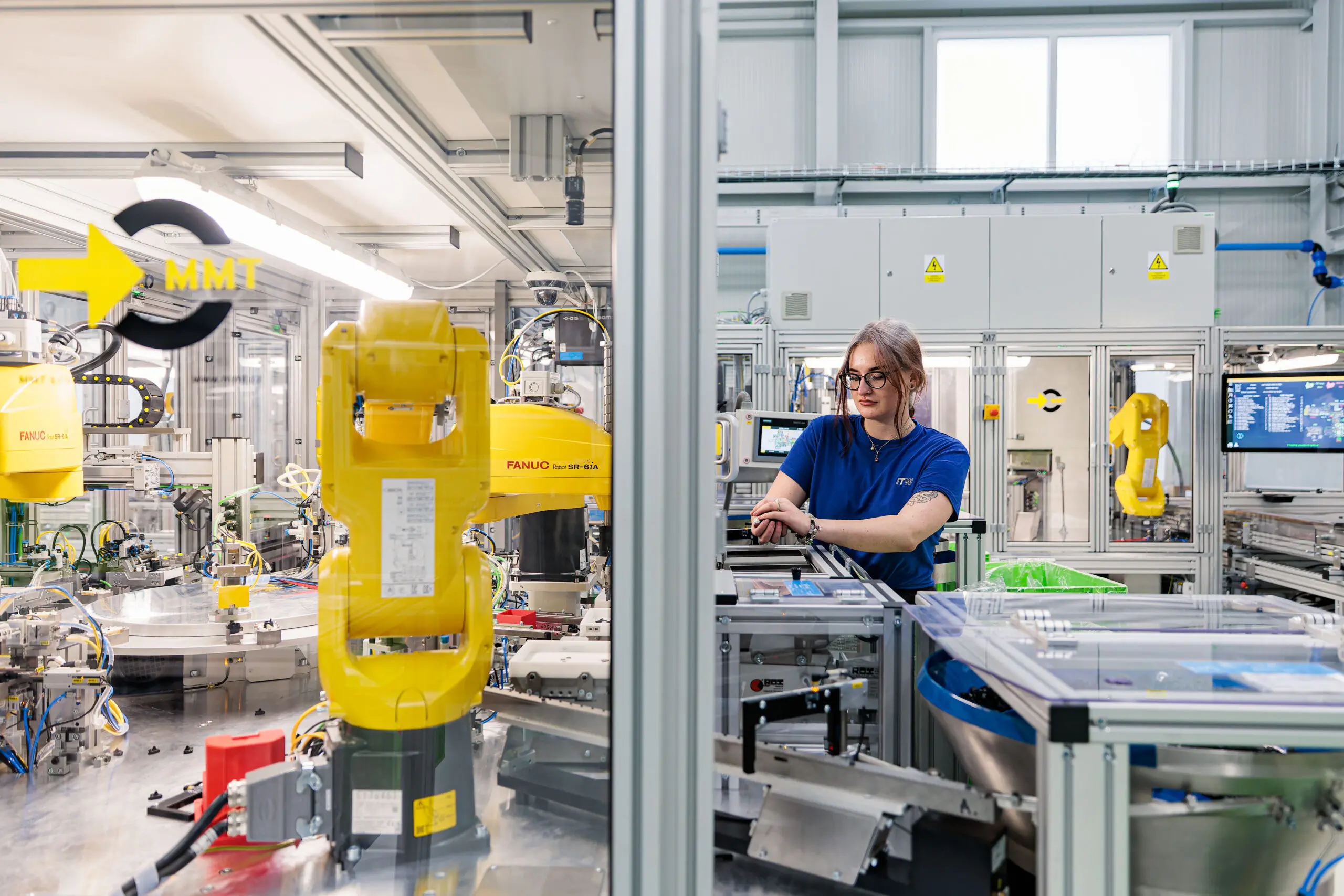

Your parts will be made in state-of-the-art plants using the latest in technologies, materials and manufacturing processes, from multi-component molding for our plastic parts to integrated computer support and automated material handling to ensure on-time delivery. Above all, your products will be made by people committed to exceptional quality and contributing to your success. Year after year, we prove it by delivering billions of reliable parts to customers like you.

Applications

Better solutions. Better outcomes.

We partner with our customers to create custom components, fastening and assembly solutions to address the most complex engineering challenges across the entire vehicle.